Engineers worldwide have been using computational fluid dynamics (CFD) to solve complex water flow challenges for over two decades now, and the market for this powerful tool is only set to expand.

So what is this tool, how are we using it at WMS and why are we enthusiastic about training our next generation of hydrologists to use it? Let’s find out.

What is CFD modelling?

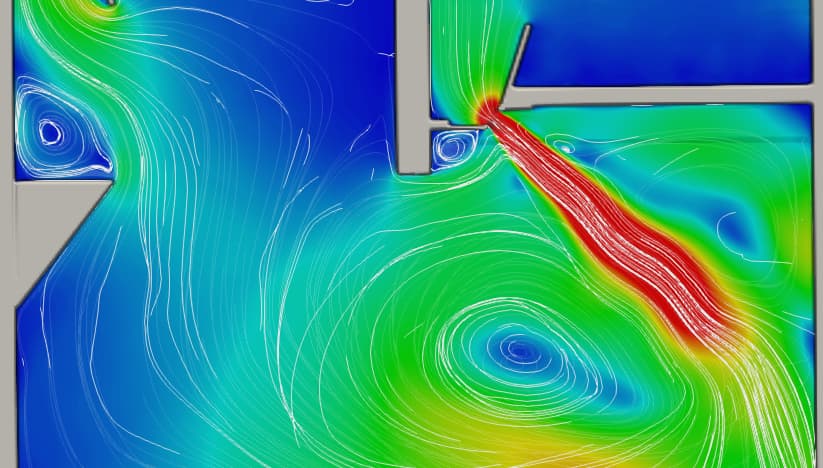

Computational Fluid Dynamics is a powerful numerical tool that helps engineers see and understand fluid flows without having to do any real-life testing.

Unlike 2D models, CFD assessments can use 3D models from the start, preserving important design features and providing useful input early in the design process.

What are the benefits?

Essentially, CFD modelling streamlines the design process so that potential problems can be spotted and avoided before projects are built. We’re able to create new equipment or scale up systems in a simulated space which helps us use energy smartly, and come up with efficient designs. This means businesses can spend less on building and running their systems.

Being able to test, design and run systems freely means that we are able to secure the best results to meet specific goals. Plus, as technology and computers get better, this technology will only become more effective and efficient.

How do we use this tool at WMS Engineering?

Our engineers at WMS use CFD modelling (FLOW-3D) for various applications, including bridge and culvert optimisation, dam spillways, pumped hydro systems, weir design, fish passage design, and improving water and wastewater treatment plant performance.

Service Spotlight: Inland Fish Passage, NSW

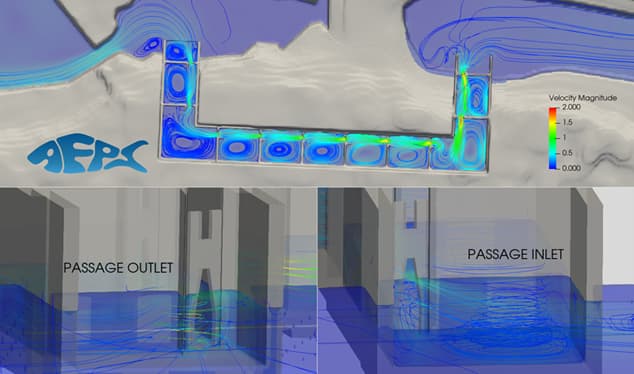

WMS engineers used FLOW-3D software to assess how a new fish passage in inland NSW would affect water volumes.

To assess the impacts, we built a FLOW-3D model of the current low-flow pipe and checked its accuracy using HEC-RAS 1D. We then tested four different baffle options for the new fish passage, removing the low-flow pipe in each case. Finally, we compared the results to see the likely volume changes for each option.

CFD modelling was the best choice for this project because it allowed us to accurately simulate the flow of water through the proposed fish passage and test various baffle options to find the most efficient design.

This precise modelling helped minimise the impacts on water volumes, ensuring that the new passage did not negatively affect the surrounding environment. Overall, CFD modelling was advantageous in that it enabled our engineers to:

- Optimise the fish passage design to maximise its effectiveness in facilitating fish movement

- Minimise construction and maintenance costs

- Support the long-term success and sustainability of the project

Training the next generation of engineers

At WMS, we recognise the importance of equipping budding hydraulic engineers with the skills they need to excel in the industry. That’s why we offer comprehensive training in FLOW-3D software to ensure that our engineers are well-versed in this powerful modelling tool.

New hires will be able to learn how to harness this cutting-edge technology to optimise exciting projects all over Australia, such as our Inland Fish Passage project. By providing our team with this expertise, we empower them to design and implement effective, sustainable water management solutions for Australia’s future.

To see current roles, visit https://watermodelling.com.au/careers/.